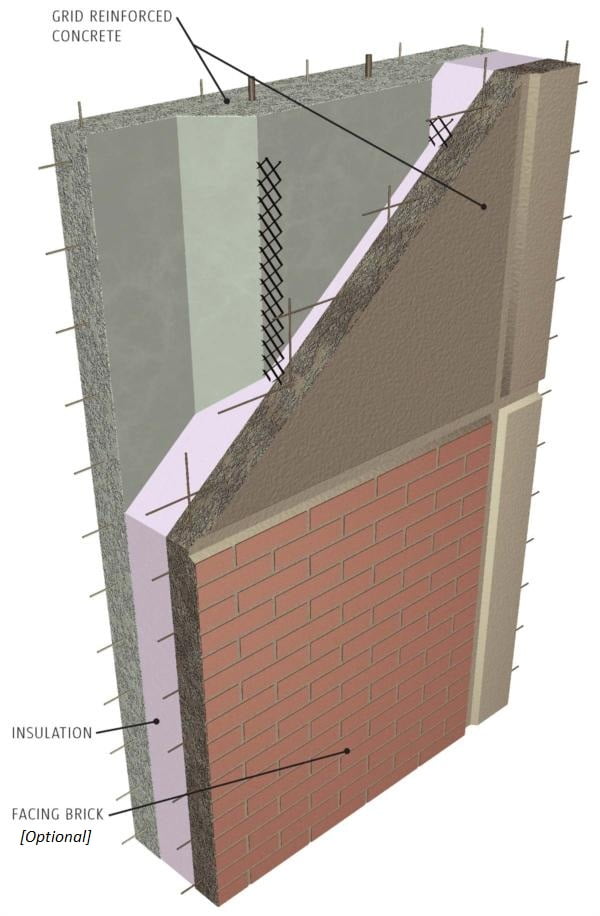

Standard & Insulated Wall Panels

Designing with standard and insulated wall panels has unlimited opportunities.

- Flexible – Owners, designers, and builders now have more flexibility than with any other material including aesthetics, functionality, color, shape, surface and texture.

- Custom Built – Custom forms can be built to fit any specifications as well as introduce reveals, joints, patterns and other detailing to the panel surface.

- Custom Finishes – Textures can be further customized via chemical retarders and mechanical treatments ranging from acid washes to sandblasting.

- Cost-Effective – Architectural panels are also economical to produce, erect and maintain. Substantial cost savings can be achieved with repetitive production techniques and early consultations with Pre-Cast Concrete Company. Panels can be produced year-round, regardless of weather conditions

- Durable – Pre-cast concrete panels provide long-term durability with little to no maintenance.

- LEED & Green Building – The panels help achieve LEED certification in a variety of ways, including their ability to be recycled, local manufacturing capability and thermal mass and insulated cores. All of these attributes help reduce the expended energy needed to manufacture, transport and erect materials, which are key LEED requirements.

Description

PRE-CAST & PRE-STRESSED CONCRETE

11360 Lang St

Anchorage, AK 99515

| Office Phone: | (907) 348-6730 |

Fall Hours as of 10/21/25: | |

| Monday - Friday: | 8:00 am - 4:00 pm |

| Saturday - Sunday: | Closed |

| CEZAR PLASCENCIA | |

| Assistant Manager | |

| Desk: | (907) 348-6732 |

| Mobile: | (907) 230-6979 |

| [email protected] | |

| DANE SMULICK | |

| Precast & Pre-Stress Manager | |

| Desk: | (907) 348-6731 |

| Mobile: | (907) 980-7626 |

| [email protected] | |